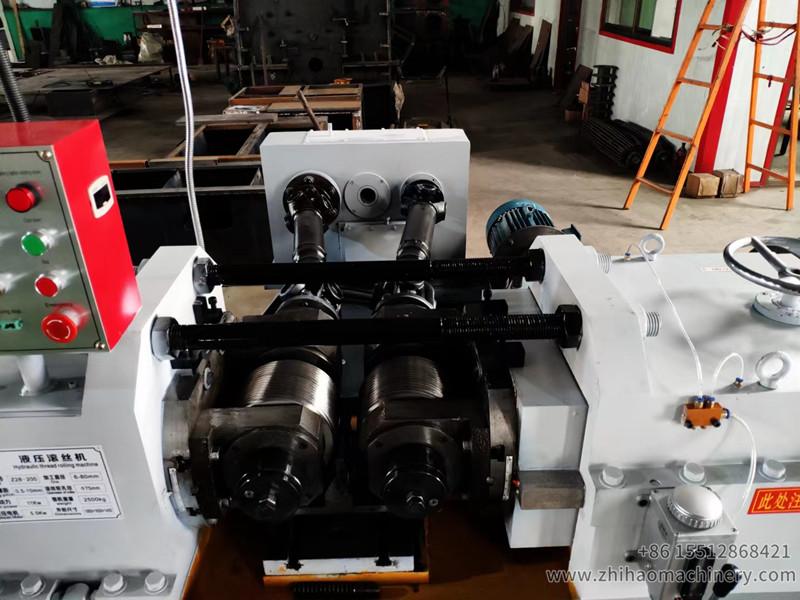

Model: Z28-215 Industrial Automatic metric M thread Thread Rolling Machine in Algeria

Max rolling diameter: 80mm

Max rolling thread pitch: 8mm

Brand: ZHIHAO

Description: Thread rolling machine is a kind of multi-function cold extrusion forming machine, and the spinning function can process the thread, straight grain and twill rolling in the cold state within the range of the rolling pressure

Z28-215 Industrial Automatic metric M thread Thread Rolling Machine in Algeria

Technical parameter of algeria thread rolling machine:

Z28-215

Rolling thread range Diameter 80mm

Max thread pitch 8mm

Spindle angle ±10° Max rolling pressure 300kn

Spindle RPM 22/28/35/45/56/70rpm

Roller size range Outside diameter 220mm

Hole 75mmMax width 150mm

Rolling time 0.1-99.9s

Rest time 0.1-99.9s

Spindle drive power 11kw/6grade

Hydraulic transmission power 5.5kw

Cooling pump power 90w

Dimension 1950*1700*1550mm

Weight 2800kg

Algeria thread rolling machine is a multi-functional cold extrusion machine tool. The thread rolling machine can roll the workpiece with thread, straight grain and twill in cold state within its rolling pressure range; Rolling of spur, helical and helical spline gears; Straightening, reducing, rolling and various forming rolling. The machine has an electro-hydraulic execution and control system, which can select each working cycle in manual, semi-automatic and automatic modes. Wire rolling cold rolling process is a kind of non cutting processing, which can effectively improve the internal and surface quality of the workpiece. The radial compressive stress generated during processing can improve the fatigue strength and torsional strength of the workpiece. It is an ideal process with high efficiency, energy saving and low consumption.

Automatic thread rolling machine is divided into two axis M thread rolling machine and three axis M thread rolling machine.

1. Two axis wire rolling machine has strong advantages in hardware construction, auto parts, transportation and power, standard parts production, etc;

2. In the pipe thread processing industry, the three-axis thread rolling machine has equal triangular support to ensure true roundness, concentricity and perpendicularity.

How to properly maintain the wire rolling machine during operation:

1. The operator can only operate after passing the examination and obtaining the operation certificate. The operator should be familiar with the performance and structure of the machine and abide by the safety and shift handover system.

2. Before work, oil shall be injected in strict accordance with the lubrication regulations, and the oil quantity shall be appropriate, the oil circuit shall be unblocked, the oil mark (window) shall be eye-catching, and the oil cup shall be clean.

3. Check whether the fasteners at all parts are loose, whether the control mechanism is flexible and reliable, and whether the safety protection device is in good condition.

4. Before operation, start the machine tool for idling for 5min - I omin, and start operation only after confirming that the lubrication, hydraulic, electrical system and transmission parts operate normally.

5. According to the process requirements of the machined parts, correctly sel

ect and install the thread rolling die, rolling die and straightening die, and correctly adjust the tooth position and end face of the thread rolling die and the taper of the thread of the machined parts. When machining large workpieces, try to shorten the span of the two fulcrum bearing seats of the fixed spindle and the movable spindle to improve the stiffness of the spindle; When cantilever rolling is used for processing small workpieces, the rolling pressure shall not exceed 58800n, and the width of wire rolling die shall not exceed 40mm

6. Always pay attention to the operation during work and keep the interlocking, limit, feeding and other mechanisms accurate and reliable. In case of any abnormality, timely check and handle it.

Any more questions for Algeria thread rolling machine, pls contact us freely.

Email: sales@zhihaomachinery.com

Whatsapp: +8615512868421

Contact: kitty

Phone: +86 15512868421

E-mail: sales@zhihaomachinery.com

Whatsapp:+86 15512868421

Add: XingWan Industrial Zone, Xingtai CIty, Hebei province, China.